Machining

Machining that meets your specs - Excellence Together

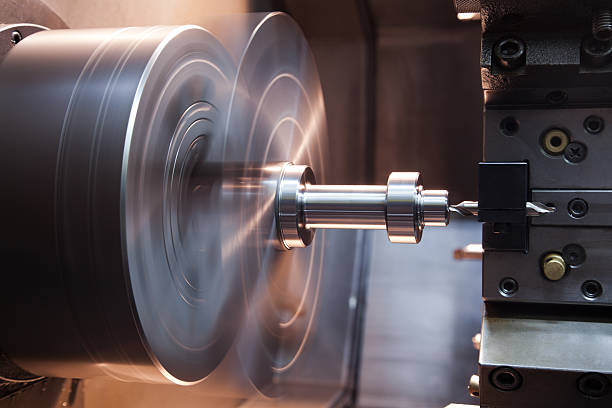

Advanced Machining and Manufacturing Excellence

We have own subsidiary with well-equipped Machine Shop which is having CNCs, VMCs , HMCs which has all the advanced facilities under one roof. The state-of –the-art machining technology and modern manufacturing concept like lean sigma enables us to produce high quality machined castings and deliver on-time.

We have strengthened our infrastructure base with advanced and sophisticated machineries for developing a wide array of high quality machined steel castings.

The distinctive array of machinery installed in our unit, our expertise in this sphere and the modern manufacturing concept lean sigma for tooling, scheduling and process control enables us to deliver high quality steel machined components with the best lead time in the industry.

Capabilities

Precision Machining Capabilities

Our machine shop is equipped with advanced CNCs, VMCs, and HMCs, allowing us to perform both rough and finish machining with exceptional accuracy. With state-of-the-art technology and lean sigma practices, we achieve tight tolerances of +/- .015mm, ensuring high-quality steel machined components with industry-leading lead times.

Tolerances of +/- .75mm

Tolerances of +/- .015mm

MACHINES

- Seven vertical turning machines with swings up to 84-inches in diameter

- Seven conventional engine lathes with swings up to 84-inches in diameter

- Six Giddings & Lewis horizontal boring mills

- Two multi-pallet horizontal machining centers

- One CNC Engine Lathe up to 80″ swing

- Two 5 Axis vertical machining center